A.D.A.M. - new standards of regenerative medicine

TECHNOLOGY

In August, 2020, FDA confirmed 510(k) eligibility for A.D.A.M. biopolymer and bioceramic bone implants. No human trials are required. FDA clearance is expected in 2024

Indications for use

Orthopedic surgery

CMF, neuro-, and plastic surgery

Oncology

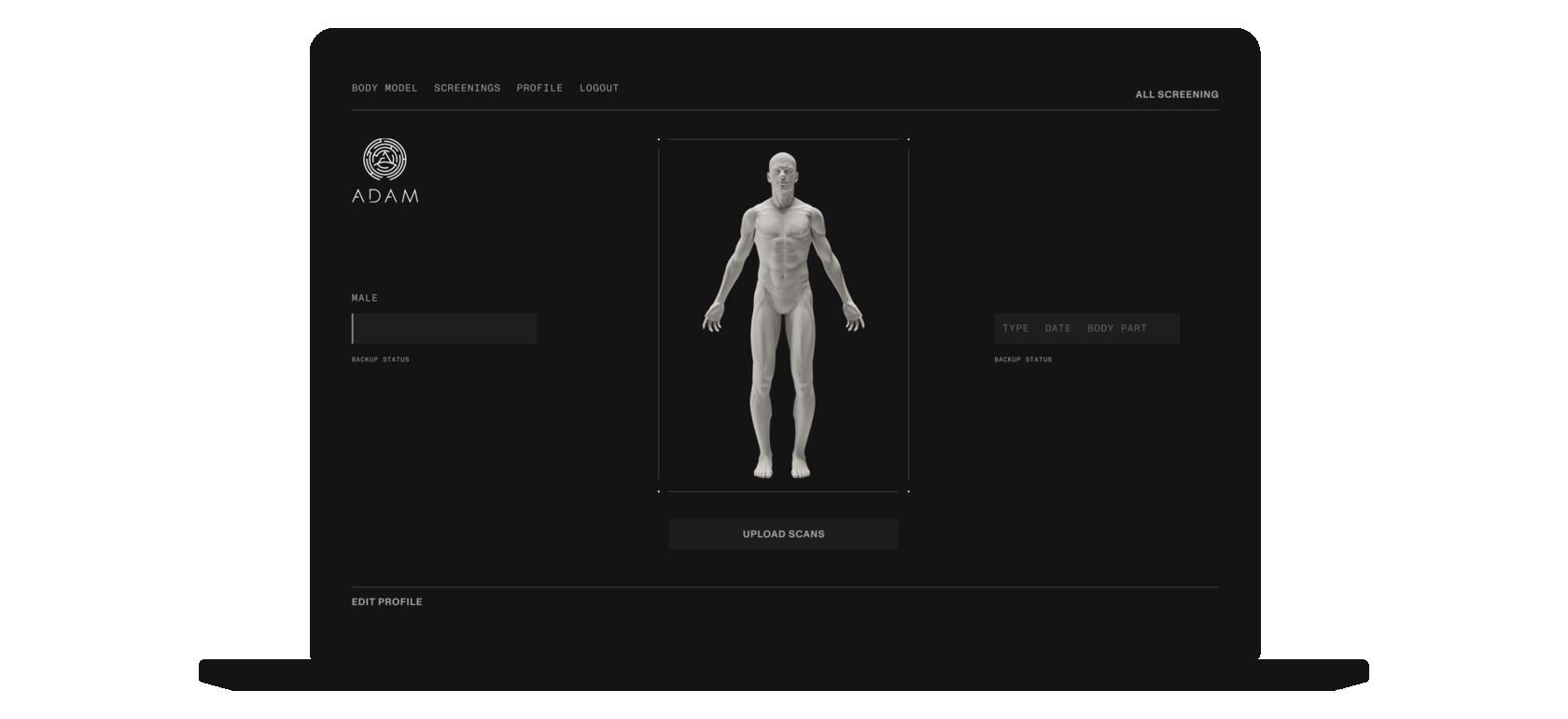

STEP 1

Patients may upload and securely store their MRI and CAT scans on the digital platform. Should the patient be in need of the bone implant, certified clinicians would be able to use the platform to create a 3D model of the implant based directly on the patient's medical data.

IMPLANT MODELING

STEP 2

IMPLANT PRODUCTION

The resulting 3D model of the patient-specific bone implant will be used for its subsequent production using A.D.A.M. proprietary 3D printers. Printing may take place at A.D.A.M. or directly on site, subject to the medical institution's preferences.

Overall production time will take up to 24 hours, which is substantially faster compared to the existing alternatives. At the same time, use of 3D-printing technology and A.D.A.M. material composites results in a lower cost of production than for titanium or PEEK-based implants.

Overall production time will take up to 24 hours, which is substantially faster compared to the existing alternatives. At the same time, use of 3D-printing technology and A.D.A.M. material composites results in a lower cost of production than for titanium or PEEK-based implants.

A personalized bone, just like yours.

With no toxic, allergic, and teratogenic effects.

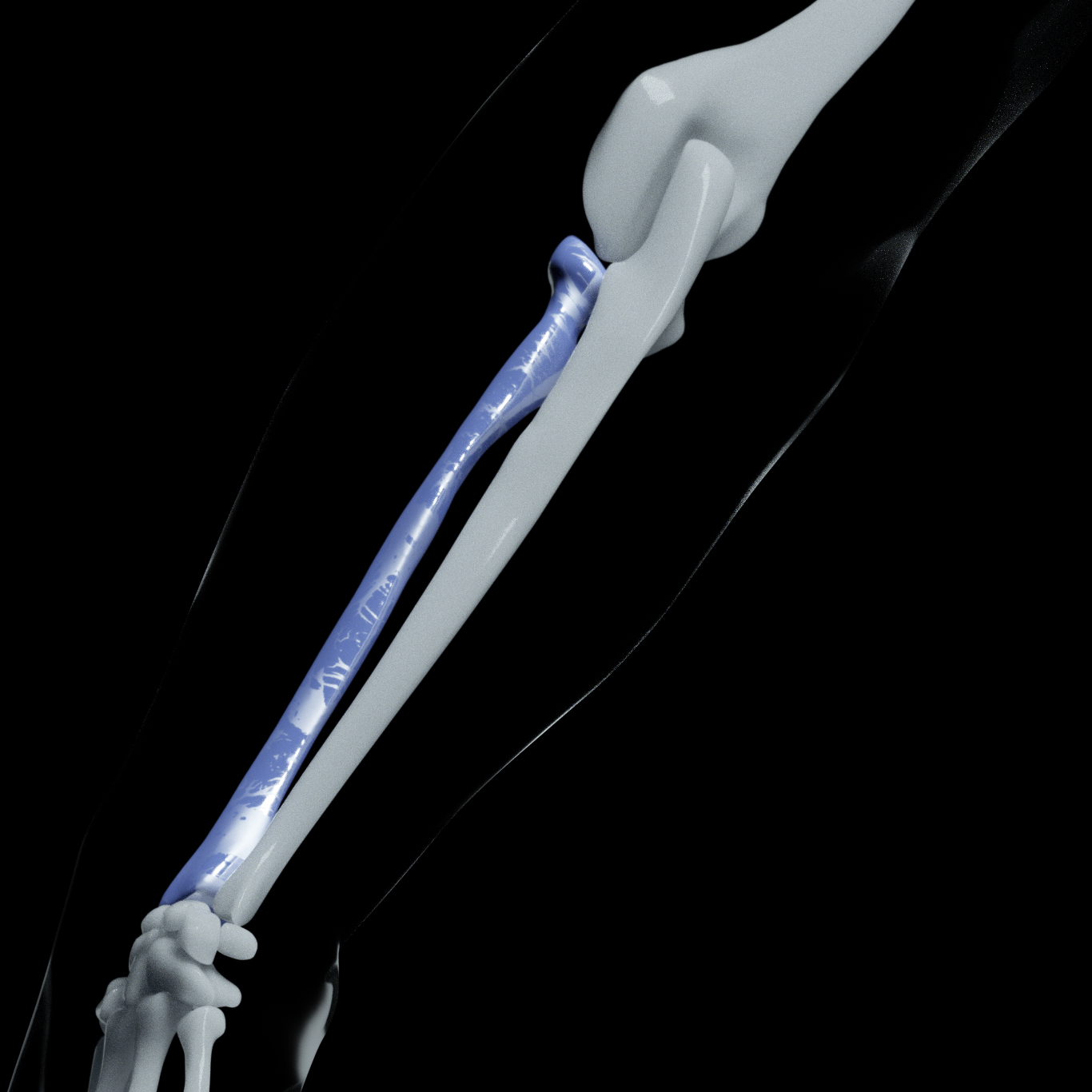

Modified biopolymer for tubular bone implants

Ceramic bio-glass for flat bone implants

- Provides high bioactivity

- Highly porous

- Stimulates osteogenesis

- Bioresorbable

Printing method: Binder Jetting Printing (BJP)

- Imitates natural bone structure

- Suitable for weight-bearing bones

- Stimulates osteogenesis

- Biodegradable

Printing method: Fused Filament Fabrication (FFF)

STEP 3

IMPLANTATION

A.D.A.M. will help medical professionals through a developed set of Quality Management System procedures, which will ensure safety, efficacy and quality of the implant.

Medical professionals will receive a sterilized 3D-printed bone implant ready for use in surgery.

Medical professionals will receive a sterilized 3D-printed bone implant ready for use in surgery.

STEP 4

RECOVERY

A.D.A.M. bone implants are biodegradable. They stimulate osteogenesis and are fully replaced by the bone tissue over time. Therefore, there is no need for reoperation to extract implant elements.

No hematoma, edema, scarring, degenerative changes, tumors, tissue necrosis and other abnormalities

Pre-clinical trials data:

Polymers

Ceramics

In the 4th week - cell migration and germination of the connective tissue (T) deep into the implant due to the porous structure of the ceramic material; in the 12th week - intensification of the process.

Formation of connective tissue capsule

Active phagocytic processes, partial destruction of test material and phagocytosis of cell metabolism products

local germination of connective tissue strands deep into the implanted material; increased neovascularization and formation of a large number of capillaries

- Pre-clinical trials completed in accordance with ISO standards

- Safety, biocompatibility and resorbability tested and confirmed

- FDA Q-submission response confirmed 510(k) rule eligibility

- No human trials required

- 2 PCT patents published (materials)

- Mount Sinai Innovation Partners' Elementa Labs startup

Bones are just the beginning. In future A.D.A.M. aims to deal with other tissues.

Expected market launch in 2024

A.D.A.M. mailing list

Stay up to date with A.D.A.M.'s progress and be the first to know when we go to market

Contact us

UConn Technology Incubation Program

9 W Broad St

Stamford, CT 06902

9 W Broad St

Stamford, CT 06902

93 Kanatna St

Odesa, Ukraine

65039

Odesa, Ukraine

65039

© 2021 ADAM • PRIVACY

3 Dorohozhytska St,

UnitCity B9, 2d floor

Kyiv, Ukraine

04078

UnitCity B9, 2d floor

Kyiv, Ukraine

04078